Making Improvement a Part of the Routine

A key part of the leaders role is to look beyond the day to day horizon to build on existing good practices and avoid past pitfalls with the aim of improving future performance.

That involves a mix of working sessions to understand causal factors and identify how to establish new standards and ways of working. The implementation of those enhancements requires training, coaching and feedback to develop skills and assure compliance. Here is how to do all of that as part of the routine.

Achieving this approach will involve changing elements of the work routine. Particularly how tasks are prioritised. Use small practical projects to identify what needs to change and how to make it happen.

To make this proactive rather than reactive, define where you want to be in 12 months time. What does good look like and how will you measure success.

Take time to define both performance gains and the cultural change to lock that into place. Then define the milestones to deliver that goal using 90 day cycles of activity carried out alongside the daily routine.

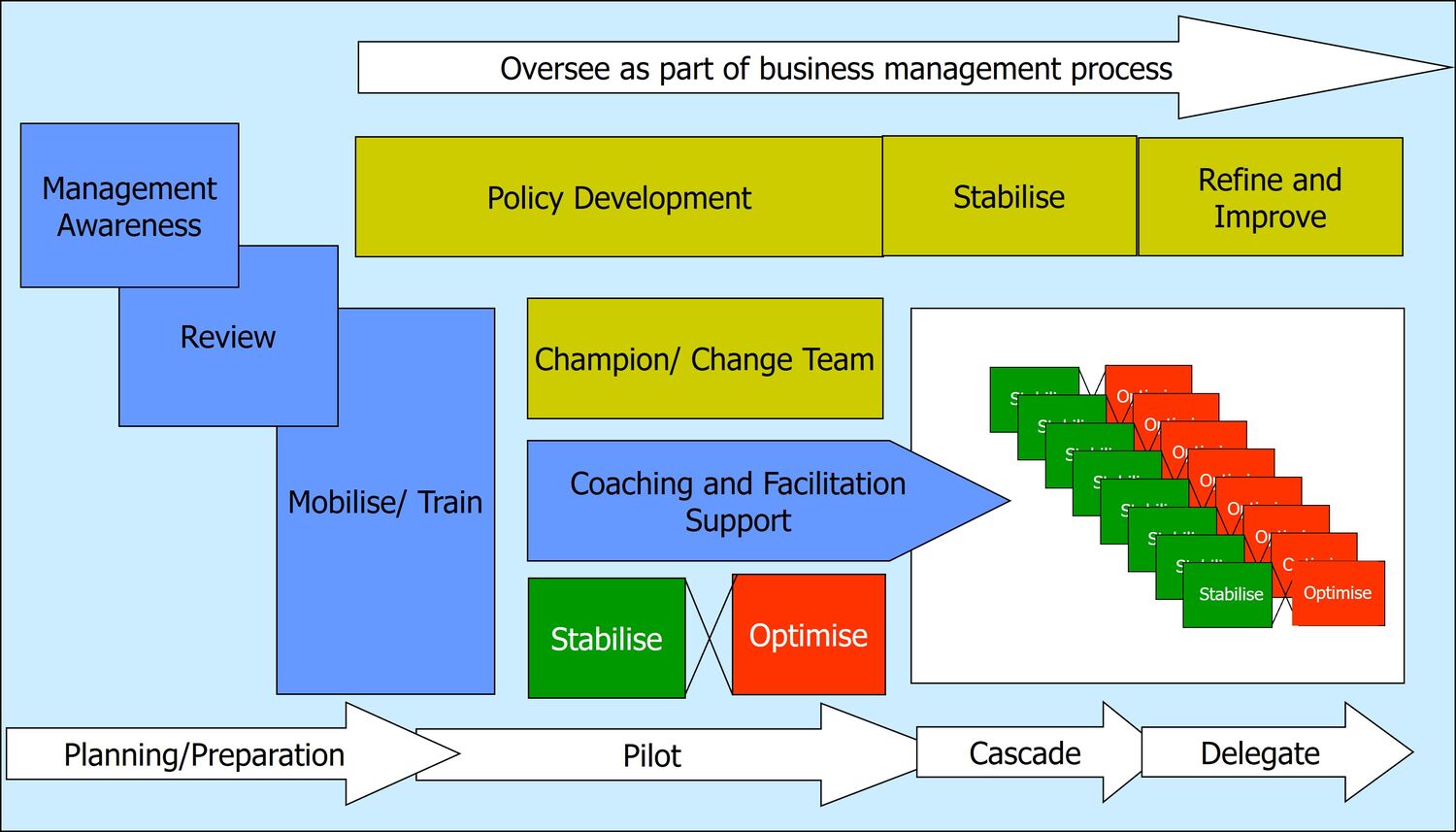

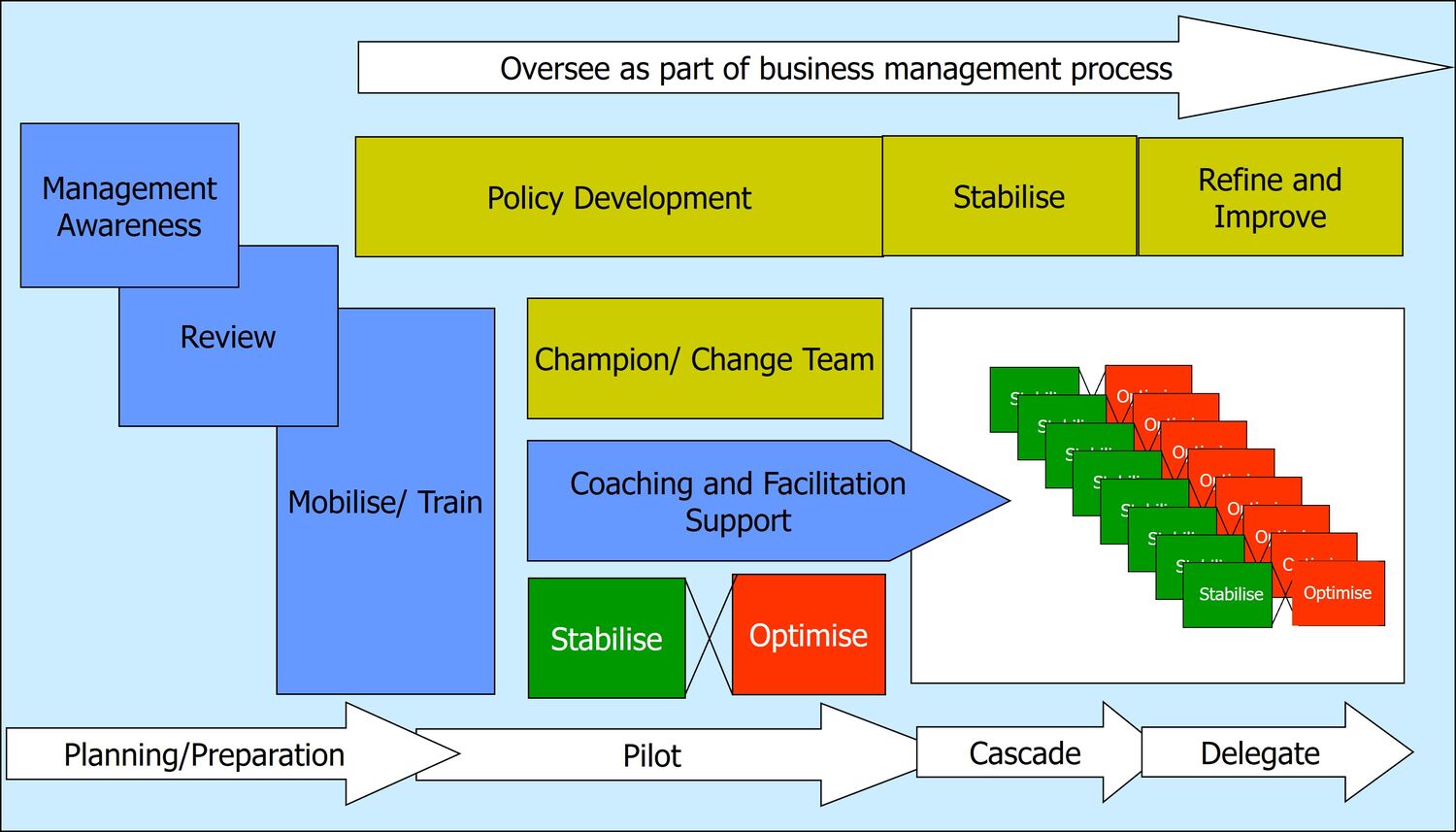

The graphic below provides an overview of how to approach the change and stack the cards in your favour so that you avoid the common pitfalls.

Figure 1: LeanTPM Roadmap Implementation Milestones

Planning and Preparation

The first steps are a Management Awareness and Review activity to agree barriers, gaps and priorities for action, That supports the development of a mobilisation programme to launch the pilot phase of the Roadmap programme.

Pilot

Start small using practical projects around troublesome assets to:

- Build shift/area team capabilities

- Develop the insight of what is needed to underpin year on year improvement in effectiveness.

- Raise operational resilience and release time to progress through the road map capability levels.

The initial project(s) provides local and senior leadership with the hands on experience to identify how to:

- Stabilise and ratchet up effectiveness as part of the daily management routine.

- Identify practical improvement actions.

- Engage front line teams with systematic development of capabilities to deliver year on year improvement of asset effectiveness.

- Develop a practical roll out cascade to transfer lessons learned across the organisation.

Roll Out cascade

Develop a blueprint for transferring the lessons learned from the pilot process to other areas as part of the pilot programme. Typically this will involve a phased approach to allow time to develop new capabilities and working relationships.

Delegate

As new ways of working improve effectiveness, management and specialist routines are simplified and can be transferred to front line teams. That also locks in the gains and supports the development of high performance teams.

Accelerator Workshops

To mobilise your programme, consider the use of our DAK Academy short 1 and 3 day accelerator workshops. These are:

DAK Academy also supports internal training academies providing training and coaching using practical TPM and Lean improvement projects that simultaneously develop Local Leader, Front Line and Senior Leader capabilities to surface gaps, overcome barriers to progress, refine ideas and apply new thinking to real world situations.

For more information message us via the contact form or